Ampoule Blister Packing Machine (blistering machine) including vial blister packing machine is cGMP machine designed for Cold Forming (ALU/ALU) with option of having Thermon Forming (PVC/ALU) blister packs. This machine is suitable for large production batches in pharmaceutical industry. We have used the best ideas from the past and developed with the future. The main movements are mechanical and pneumatic, all the control systems used in the equipment are the best in the electronic market.

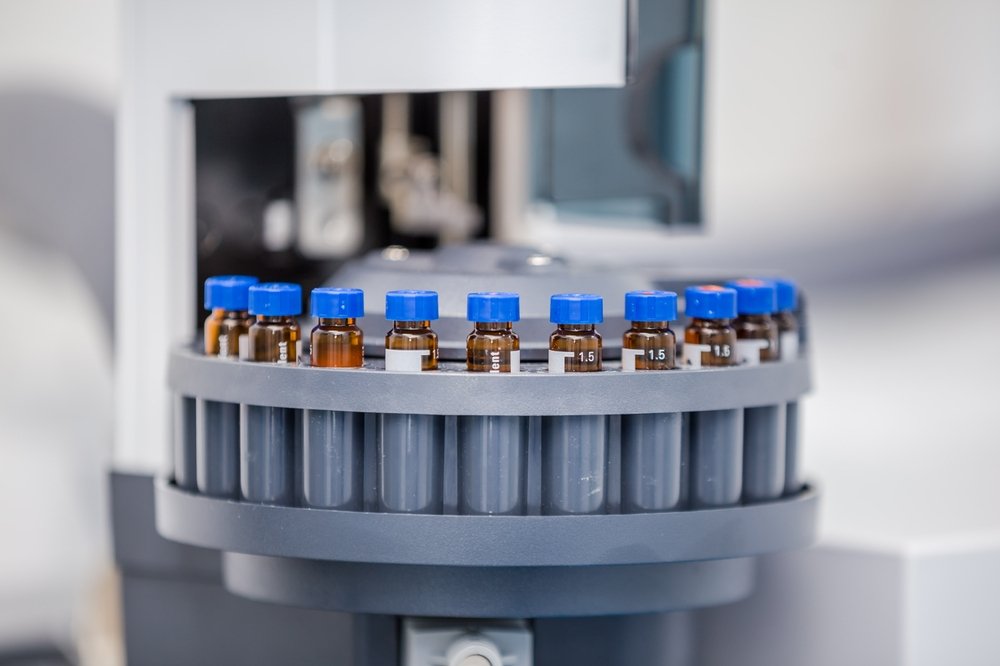

Adinath is one of the leading blister packing machine manufacturer in India offers complete range of single-track blistering machine and double track blistering machine. These machines use for packaging of ampoules in blisters and vials in blisters. It is also called and Ampoule Blistering Machine and Vial Blistering Machine.

The basic machine body made of mild steel chassis with SS 304 frames welded and bolted from a rigid frame device structure on which various modular stations are mounted in balcony design. All the drive component and extensive cabling are located behind and inside the machine the various stations of the machine are controlled by the centrally mounted spline shaft driven by Main motor. There are two servo motors for operating the Indexing and the feeding system of the machine. The Feeding is done by Product Transfer Roller (PTR) for Alu/Alu Blister accurately. The entire machine is mounted on the six height adjustable studs so that the entire area below the machine is easily sanitized. The machine will be properly guarded to ensure operator safety. The cantilevered modular stations adjustments are accessed from the front side of the machine. The format parts are very easy to mount and dismount and are achieved using minimum tools and tackles. A complete set of changeovers can be achieved in less than 30 minutes with minimum operator fatigue.

|

DESCRIPTION

|

COLD FORMING ALU-ALU |

THERMO FORMING (WHEN FITTED) |

|

Base Film Width |

Alu. Foil 150 mm |

PVC Film 150 mm |

|

Film Thickness |

Alu. 0.13-0.15 mm |

PVC 0.20 – 0.40 mm |

|

Reel Dia. |

Alu. 440 mm |

PVC 440 mm |

|

Sealing Foil Width |

150 mm |

150 mm |

|

Sealing Foil Thick |

0.02 – 0.04 mm |

0.02 – 0.04 mm |

|

Sealing Foil Dia. |

210 mm |

210 mm |

|

Pack Length |

140 mm |

140 mm |

|

Pack Width |

100 mm |

100 mm |

|

Forming Depth |

12 mm |

12 mm |

|

Cycle Speed/Output |

Up to 30 Cycles/Minute |

Up to 30 Cycles/Minute |

|

Overall Dimensions (Approx.) |

Length: 3000mm approx. |

Length: 3000mm approx. |

|

Width: 950mm approx. |

Width: 950mm approx. |

|

|

Height: 1700mm approx. |

Height: 1700mm approx. |

|

|

Net Weight (Approx.) |

1050 Kgs. approx. |

1050 Kgs. approx. |

|

Utilities Requirement |

||

|

Compressed Air |

24 CFM dry air at @ Pressure of 8 Kg/Cm 2 |

|

|

Water Cooler |

80 Liters / Hour Inlet pressure = 2.5 bar (Max) | |

|

Water outlet Temp. = 15 ± 2° C |

||

|

Connected Load |

4.5 K.W. |

|

|

Electrical Power |

415 V ± 10%, 3 Phase, AC, 50 Hz ± 2 Hz (4 Wire) |

|

|

Earthing Cable |

Copper, 2.5 mm² (Minimum) |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.