Rotary Vial Washer or rotary vial washing machine is specially designed to wash vials with minimum contact of machine parts with the vials compiling cGMP standards. Machine with specially designed Gripper system holds the vials from Neck and invert the vial till the washing operation completed and again after washing release the vial on outfeed feedworm system in vertical position ensures positive wash of vials. Machine is suitable to wash 2ml to 100 ml vials with the help of change parts

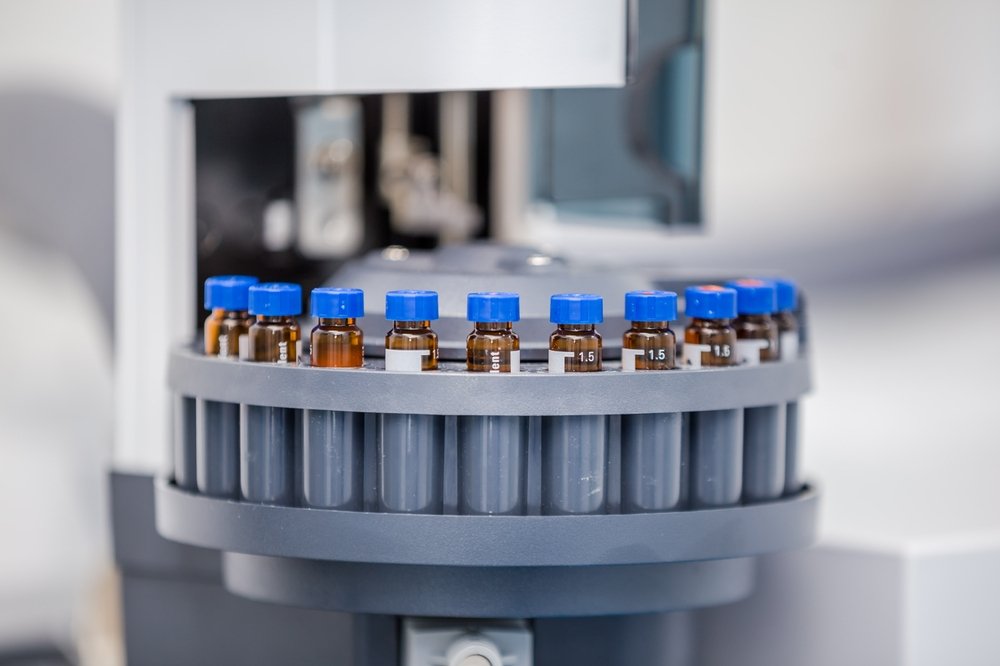

Absolute cleanliness and hygiene is paramount in pharmaceutical filling and packaging processes and this becomes of even more importance when you consider injectables filled into glass vials. Each injection vial must be absolutely sterile before it goes into the sterile filling area. Adinath, the leader in high technology pharmaceutical machinery offers a high precision vial washing machine that meets today’s high standards of sterility and hygiene.

Vial feeds through feedworm to infeed Star Wheel and specially designed Gripper hold the vial from neck and invert the vial and move it further on rotary moving system for washing process. Vials traveling in neck down position above washing needles and moves along with the Needle bar ensures maximum time for washing once the needle enter in the vial neck. Machine with Standard Six Different Washing Stations each of 6 Needle for optimum Washing and the sequence can be change as per customer’s requirement. Machine also having external wash for optimum washing of vial. We are having two different models in this machine. AVRW-120 Automatic Vial Washing Machine provided output up to 100 vials per minute whereas AVRW-240 High Speed Vial Washing Machine provided output up to 200 vials per minute. Both the vial washers (automatic vial washer and high speed vial washer) can wash 2ml to 100ml vials. We provide extended support for vial washing machine change parts and vial washing machine validation.

Machine finished with stainless steel finish & all contact parts in SS 316 and nylon materials, also having overload clutch system to prevent jamming during the operation. The manifold comprises of inner nozzles which jets compressed air in the bottle and an outer socket, which cover the mouth of the bottle and is connected to an exhaust, ensures perfect cleaning.

Vials feed from the Infeed turn table / tray are received on Infeed Star wheel / Feed worm then moves on Infeed starwheel. The Grippers picks up the vial from Infeed Star Wheel and invert it in neck down position over washing needles and move along with the needle bar for Washing. Vials traveling in neck down position above washing needles and moves along with the Needle bar ensures maximum time for washing once the needle enter in the vial neck. Machine having six different washing stations each of 6 needles for optimum Washing and the sequence can be adjusted as per requirements. Washer also having external wash for optimum washing of vials.

On completion of a cycle, washed vials are again inverted to neck upward position and feed to output star wheel. Washed vials received from output starwheel can be collected on Output Tray or can be pushed to tunnel. A separate pumping station (optional) gives the right quantum of water at the desired pressure. In the absent of separate pumping station, we can provide the re-circulation & siliconization system on request.

The AVRW is equipped with 6 internal cleaning stations and each station has 6 cleaning needles making up a total of 36 cleaning needles. Each cleaning station is supplied via a pipe connected to the cleaning media-making washing area. This not only reduces the risk of particle generation, but also simplifies maintenance and cleaning efforts while saving time.

The 3 external cleaning stations mounted in a stationary position above the ampoule can be easily adjusted for a specific height, angle and lateral position. Each cleaning station receives cleaning media-making through a pipe connected to the cleaning media-making washing area.

WFI, Purified water and air cleaning station are synchronized with the ampoule by reciprocating motion. Design is such that these media are put to use only when needles motion in forward direction. WFI consumption is further reduced by collecting the WFI in re-circulating water tank to be used later on in the pre-washing station.

|

Model |

AVRW 120 |

AVRW 240 |

|

Production Output |

Up to 100 per minute |

Up to 200 per minute |

|

Vial Sizes |

2ml to 100ml |

2ml to 100ml |

|

Type of Vials |

Glass & Plastic Vials |

Glass & Plastic Vials |

|

Power Load |

4 H.P. |

5.5 H.P. |

|

Power Voltage |

440 Volts, 3 Phase 50 Hertz, 4 wire system | 440 Volts, 3 Phase 50 Hertz, 4 wire system. |

|

Optional Accessories |

|

|

| Utility |

|

|

|

Water Tank & Pump |

3 nos. each with 25 liters Capacity & Centrifugal pump | 3 nos. each with 25 liters Capacity & Centrifugal pump |

| Overall Dimension: | 2050mm (L) X 2000mm (W) X 1210mm (H) approx. |

2450mm (L) X 2000mm (W) X 1300mm (H) approx. |

|

Net Weight |

700 kgs. approx. | 900 kgs. approx. |

| Gross Weight | 1000 kgs. approx. |

1300 kgs. approx. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.