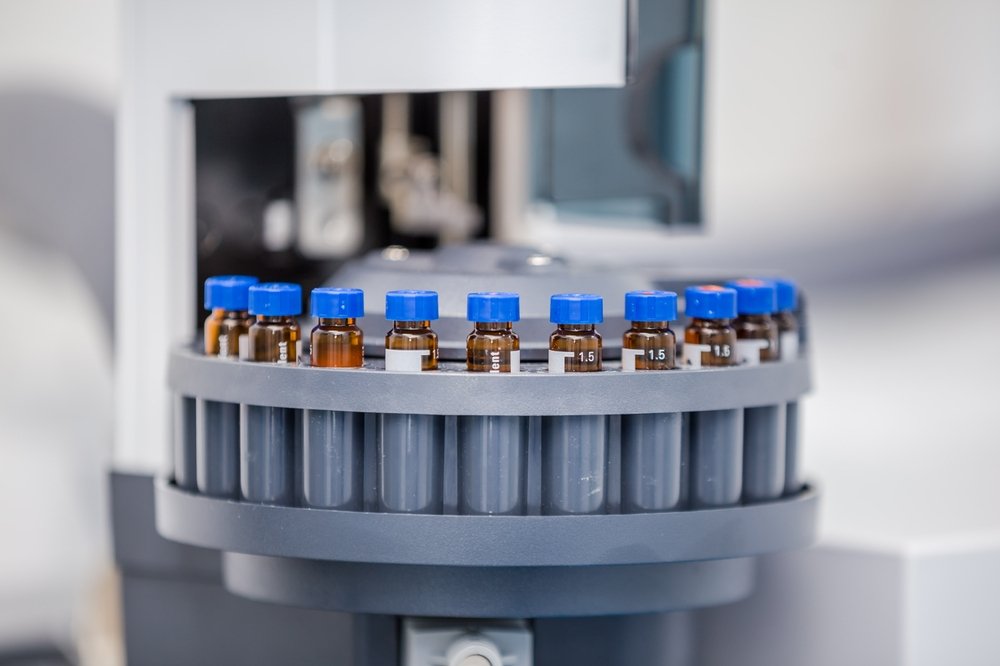

Multijet Vial Washing Machine or vial jet washer is a semi-automatic, compact, versatile and a reliable ampoule and vial Washing machine, equipped with cGMP requirements. Multijet Ampoule & Vial Washing Machine is designed with stainless steel construction with compliance to wash ampoule size of 1ml to 20ml and glass vial sizes of 2ml to 100ml with the help of suitable change parts. All contact parts are made from Stainless Steel 316L, or FDA approved materials.

This lab scale small vial washer is having timer operated solenoid valve system for observing total six washing in one cycle. Multijet Ampoule & Vial Washing Machine is widely use in medium & small-scale injectable organizations. Combi trays are made from of cast nylon materials with number of holes depends upon diameter of ampoules. There is combination of 53 holes, 100 holes, 189 holes, 240 holes and 340 holes needle plates to perform different sizes of ampoules. Our Multijet Ampoule Washing Machine can wash 1ml to 25ml glass ampoules.

Ampoules are loaded in bulk onto combi tray if received in ready to dump boxes, which will have exactly same number of Ampoules and the pitch, as loading tray. Alternatively, each Ampoule/Vial has to be arranged into the tray individually. The loading tray is placed directly into the machine & the handlebar is lowered for automatic centering of washing needles into the Ampoules neck. The top cover is lowered & switch is operated for automatic sequential washing. Washing is performed from inside and outside of each individual Ampoule. Machine automatically stops after one complete washing cycle with buzzer sound and red-light indication. For removal of tray, reverse procedure is to be observed. Depending on loading & operator’s efficiency one can achieve 30 loading trays in an hour.

| Jet Needles | Production Output |

| 56 Holes Plate | 1680 per hour approx. (56 holes plate x 30 cycles) |

| 99 Holes Plate | 2970 per hour approx. (56 holes plate x 30 cycles) |

| 189 Holes Plate | 5670 per hour approx. (56 holes plate x 30 cycles) |

| 240 Holes Plate | 7200 per hour approx. (56 holes plate x 30 cycles) |

| 340 Holes Plate | 10200 per hour approx. (56 holes plate x 30 cycles) |

| Internal/External Washing | Washing Media |

| 1st Wash | De-Mineralized Water |

| 2nd Wash | Purified Air |

| 3rd Wash | De-Mineralized Water |

| 4th Wash | Purified Air |

| 5th Wash | Water for Injection |

| 6th Wash | Purified Air |

| Model | AAVW 340P |

| Loading & Unloading | Manually |

| Washing Process | Automatic through PLC |

| Input Specification | 2ml to 100ml vials and 1ml to 20ml ampoules |

| Production Output | Up to 100 ampoules/vials per minute (depends upon needle plate and operator’s efficiency) |

| Power Supply: | 0.25 H.P. |

| Electrical Characteristics: | 220 Volts, Single Phase, 50 Hertz |

| Net Weight: | 120 Kgs. Approx. |

| Gross Weight: | 250 Kgs. Approx |

| Net Dimension: | 1200 mm (L) X 1020 mm (W) X 1080 mm (H) approx. |

| Case Dimensions: | 1350 mm (L) X 1200 mm (W) X 1280 mm (H) approx. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.