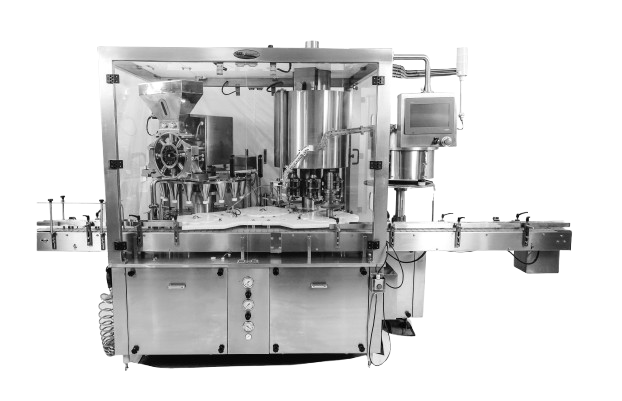

Dry Syrup Powder Filling Machine or dry syrup filling machine is powder filler suitable to fill large volume powder into PET/glass bottles. Filler suitable to fill up to 120 containers per minute depending on Powder Fill Volume, Type of Powder, Bottle Diameter and Bottle Neck Diameter

The incoming sterilized dry bottle is fed through the in-feed turn table. Suitable guide supply bottles on to flat conveyor belt at the required speed for feeding. There is filling head mounted on machine top plate in the same line.

When bottle reaches to the mechanical holder detained filling station, Bottle sensor sense the bottles and Magnetic clutch starts to rotate which is mounted on auger shaft. It fills the desired amoun t of powder into the bottle through auger, where rotation time is previously determined.

Duly filled bottles go upward on to the sealing station with the help of SS conveyor belt.

| Models | ZSADPM 12 | ZSADPM 16 |

| Production Output | Up to 80 bottles/minute | Up to 120 bottles/minute |

| Bottle Diameter | Up to 85mm | Up to 85mm |

| Bottle Height | Up to 200mm | Up to 200mm |

| Fill Volume | 5gms. To 70gms. in Single Dose with the help of change parts for different fill volume | 5gms. To 70gms. in Single Dose with the help of change parts for different fill volume |

| Fill Accuracy | ± 2% Depending upon the Powder, under the controlled level of Humidity | ± 2% Depending upon the Powder, under the controlled level of Humidity |

| Humidity | Below 28% Rh required on machine to be arrange by customer | Below 28% Rh required on machine to be arrange by customer |

| Power | 2.0 H.P. For Machine and 3.0 H.P. For Vacuum Pump | 2.5 H.P. For Machine and 3.0 H.P. For Vacuum Pump |

| Overall Dimension | 1700 mm (L) x 1000 mm (W) x 1800 mm approx. | 2000 mm (L) x 1200 mm (W) x 1800 mm approx. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.