Measuring Cup Placement Machine or Dosing Cup Placement & Pressing machine is highly efficient machine with elegant look, consists of conveyor, vibrator, container holding pressing device, & pressing belt. All the exposed parts of the unit are in S.S., chrome platted or Cladded with Stainless Steel. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet doors are provided to facilitate the servicing of machine.

Machine is widely uses in Dry Syrup Powder Filling Line and Oral Liquid Suspension Filling Line for automatic operations. It is having uses for dose placement cups in pharmaceutical, herbal and nutraceutical industry.

Automatic Measuring Cup Placement Machine suitable for placement of Measuring Cup on the sealed bottle. The Cup Dispenser Unit is located on the top plate of the machine and it also provides up‐down mechanism by screw and Ratchet Spanner we can adjust the height of the Cup Feeder required on the bottle. The container separator assembly is located on the top plate of the machine related to the conveyor. The main purpose of the container separator assembly is to maintain gap between two containers which is required for particular cup feeding procedure. It is located on the top plate of the machine and drive is synchronized with pressing belt and container separator. Pressing Belt Assembly is fitted on the top plate of the machine and main function of the pressing belt assembly is to hold the bottle till the cup placement operation is completed.

| Model | AMCP ‐ 120 |

| Production Output | Up to 100 per minute |

| Direction of Movement | Left to Right |

| Power Consumption | 1 H.P. |

| Power Voltage | 440 Volts, 3 Phase, 50 Hertz |

| Height of Conveyor** | 850 mm to 900 mm Adjustable. |

| Dimensions | 1500 mm (L) X 800mm (W) X 1700mm(H) approx. |

| Case dimensions | 1900mm (L) X 1000mm (W) X 1900mm (H) approx. |

| Net Weight | 350 kgs. approx. |

| Gross Weight | 500 kgs. approx. |

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.

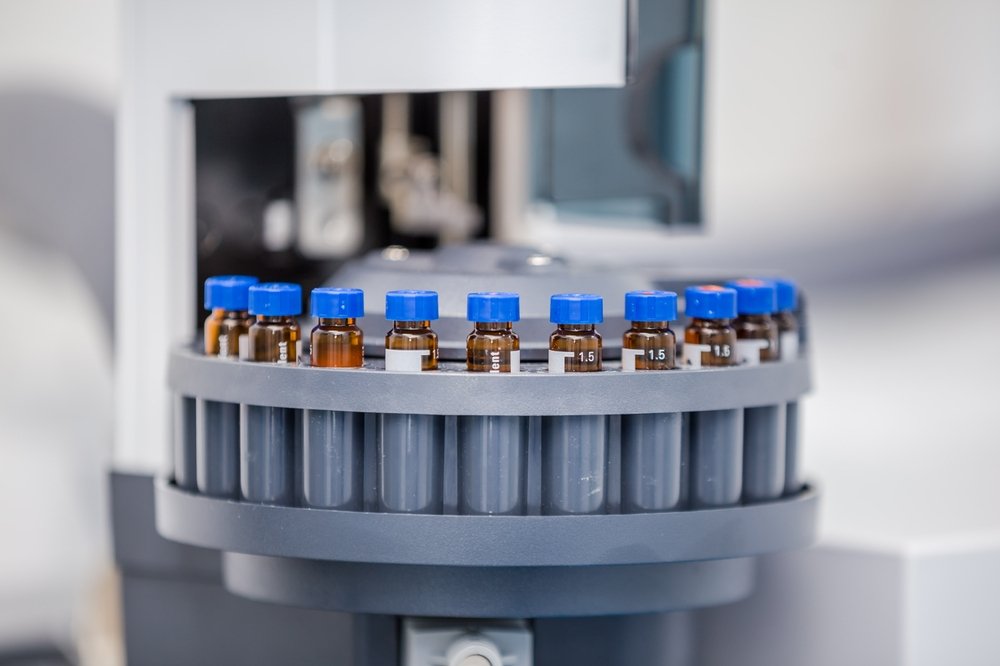

Ampoule Filling Machine of One, Two head, Four Head, Six Head and Eight head. Ampoule Filler Machine uses in Injectables which are Two Head Ampoule Filling Machine, Four Head Ampoule Filling Machine, Six Head Ampoule Filling Machine, Eight Head Ampoule Filling Machine and Lab Scale Ampoule Filling Machines. Option of Safety Cabinet/ Laminar Air Flow/ISOLATOR available as per individual requirements. Our ampoule filling machine can be categorized in below sections

Many our different models of Ampoule Filling Machine suitable as per need of small, medium & large volume sterile injectable preparations.

Single Head Ampoule Filling & Sealing Machine having output of 1500 ampoules/hour suitable for lab scale production.

Four Head Ampoule Filling & Sealing Machine having output of 6000 ampoules/hour suitable for medium scale production.

High Speed Ampoule Filling Machine having output of 12000 ampoules/hour suitable for large scale production.

We provide integrated Ampoule Filling Line which is having Ampoule Washing, Sterilization Tunnel, High Speed Ampoule Filling Machine and Ampoule Sticker Labeling Machine. These production lines available in capacity of 200 ampoules/minute and 300 ampoules/minute production range.

Our Ampoule Filling Machine suitable for filling 1ml, 2ml, 3ml, 5ml, 10ml, 20ml, 25ml and 30ml ampoule sizes. We manufacture injectable plant machineries which includes Ampoule Vial Washing Machine, Ampoule Filling and Sealing Machine, Ampoule Filler Machine, Ampoule Inspection Machine, Ampoule Sticker Labeling Machine. Apart from it we manufacture Vial Liquid Filling Machine, Vial Powder Filling Machine, Injectable Powder Filling Machine, Vial Cap Sealing Machine, Vial Labelling Machine and Dry Syrup Powder Filling Machines.