Production Scale ETO Sterilizer or industrial eo gas sterilizer has been specially designed for sterilization of products sensitive to high temperature and to humidity (Syringes, DE fluxers, Catheters, Cartridges for Dialysis, Plastic articles, Bandages, Sutures etc.). Sterilizer can be uses even for sterilization of powders which deteriorate by heating exposure. For the wide range of product that can be treated, such sterilizer find application in Disposable Surgical Products, Para Pharmaceutical and Pharmaceutical Industry, Laboratories, Hospital and Food Processing Industries.

Adinath Ethylene Oxide Gas Sterilizer Manufacturer can be realized in to satisfy different requirements working under pressure (1.5 kg/cm² + vacuum) with mixtures of Ethylene Oxide and Carbon Oxide (usual composition 10% ETO + 90% CO₂, 5% ETO + 80% CO₂)

Ethylene Oxide gas infiltrates packages as well as products themselves to kill microorganisms that are left during production or packaging processes. This gas, mixed with air at a ratio of at least 3% ETO gas, forms an explosive mixture. Pure ETO gas boiling point is 10.73 ºC at atmospheric pressure. Most of the time, it is mixed with Nitrogen or CO2. EO Gas Sterilizers uses to sterilize to surgical instruments and medical disposables.

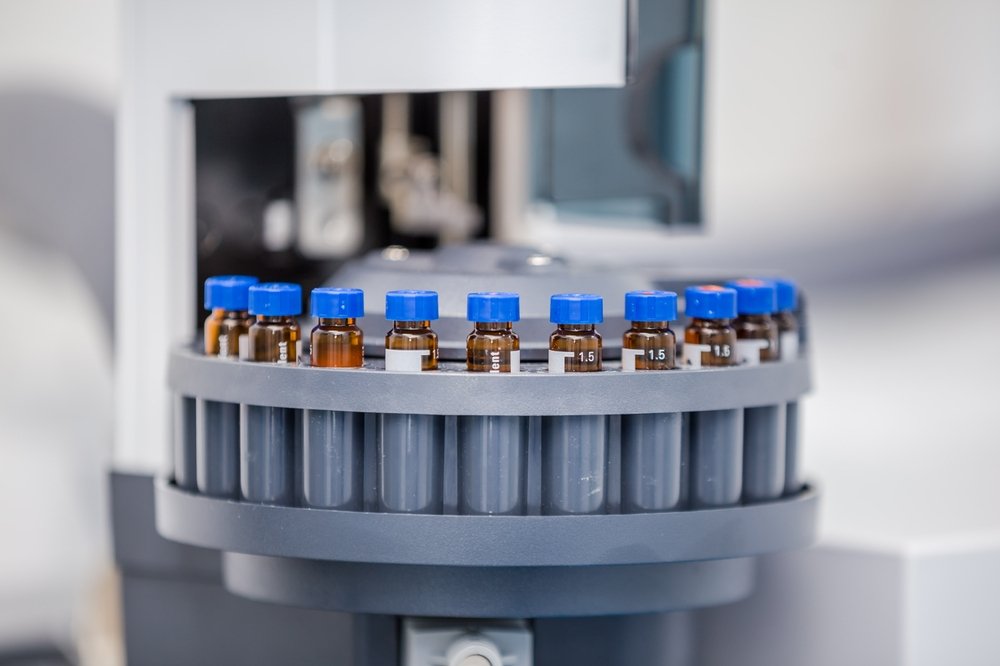

The system has been designed to operate on single use disposable type, EO 100% gas cartridges of 40 / 100 / 170 grams. The chamber and all contact parts shall be made from S.S 304. The chamber has been provided with a single door, easy locking arrangement and silicon gasket for leak proof operation. Electronically controlled heating system to ensure uniform heating of the chamber at 50 degrees centigrade. The chamber is provided with a adequate capacity rotary vacuum pump enclosed in sturdy cabinet duly powder coated for durability. We provide four of control switches with built in indicator light to regulate evacuation, feeding of gas, fresh air inlet through filter and aeration facility. Ethylene Oxide Gas Sterilization Unit is compact stand-alone sterilizer chamber.

Ethylene Oxide Sterilization (Sterilization) offers various distinct advantages over the conventional steam sterilizers (sterilizers), being a DRY & COLD (operates at 50ºC ) process proves very useful in sterilization of expensive items, also it has got a unique penetration ability, so it is very useful in sterilization (Sterilization) of expensive and delicate items such as Cardiac catheters, Stents, IOL’s Tubing’s, various types of scopes, sharp surgical instruments etc., its unique mode of action, also enhances the life of several surgical accessories & disposables items thus making them perfectly reusable.

We are one of the leading EO Gas Sterilizer manufacturer in India. We manufacture below two types of ETO sterilizers:

Usual gas exposure time is 3 to 40 hours. Sterilization time depends upon type of packaging and other process parameters.

35˚C to 60˚C set temperature value is non- stop holed by force circulation of water inside the jacket and optionally inside this system is very reliable with no risk of overheating and temperature differences by steam use.

40 to 70 RH value is obtained with sterilizer under vacuum condition to allow best conditioning of sterilization load.

Variable on the basis of used gas mixture and operating pressure.

20 Cubic Feet to 30 Cubic Meters models available as per requirements.

* Power voltage can be adjusted as per customer’s domestic power voltage requirements.

* Rights of technical improvements & modification reserved.

* Illustrations & dimensions are shown for information purpose only.